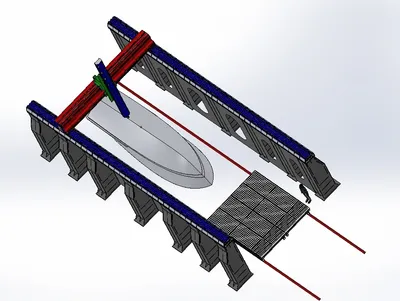

Process Extra-Large Parts with Precision

Push the limits of production with OYS Makina’s giant CNC machining centers.

Machine Models3-, 4- and 5-Axis CNC Solutions

Achieve high-speed and high-precision machining — even at exceptional scales.

ProjectsPowerful Solutions from Bursa to the World

Delivering top performance for the marine, aerospace, casting, and furniture industries.

References

Industry-Specific Solutions

• Marine Industry

• Aerospace and Defense

• Casting and Molding

• Furniture and Decoration

• Plastics and Prototyping

OYS CNC

Our Machine Models

- Composite and Wood Processing Machines

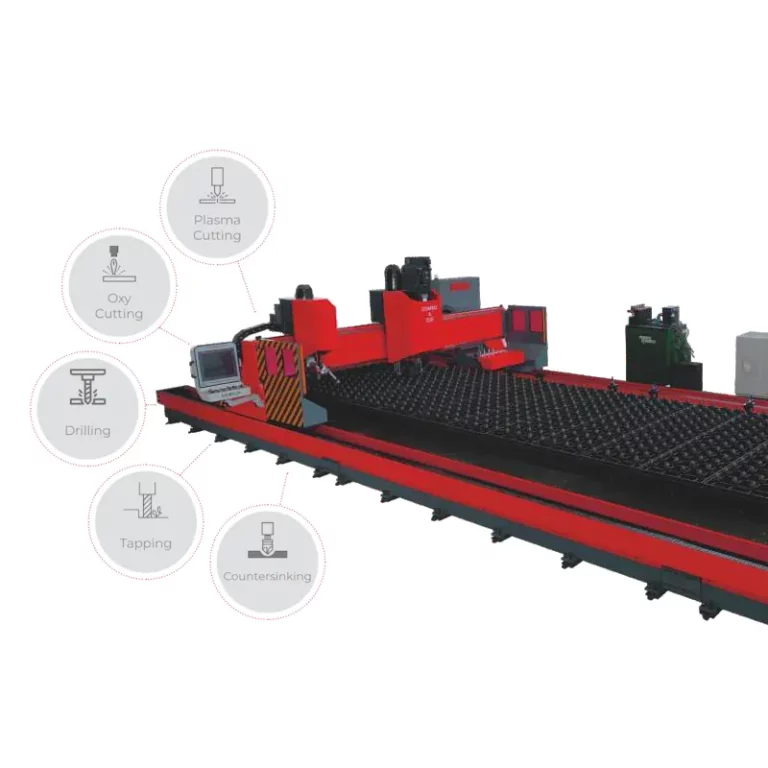

- Metal Processing Machines

- Plasma Cutting Machines

- Saw Cutting Machines

Who We Are?

OYS Makina is a trusted manufacturing partner producing 3-, 4-, and 5-axis CNC mold machining centers in Bursa, Turkey — serving both domestic and global industries with precision and reliability.

Global Strength

Our exported machines are used in a wide range of applications — from carbon racing yachts to GRP pipeline systems.

We also actively participate in major trade fairs both in Turkey and around the world, showcasing our technology on an international scale.

Why Choose OYS Makina?

- Capability for Large-Scale Parts: From yacht hulls to massive molds, designed for the most demanding production needs.

- Speed and Precision: Machining speeds between 20–80 m/min deliver maximum efficiency and time savings.

- Automatic Tool Change: Perform drilling, surface finishing, and detailed cutting in a single operation.

- Wide Material Compatibility: Superior performance on MDF, wood, foam, epoxy, composite, and advanced materials.

Industry-Specific Applications

- Marine: Precision machining of boat and yacht molds.

- Aerospace & Defense: Production of composite components and prototypes.

- Casting & Molding: Manufacturing of industrial mold structures.

- Furniture & Decoration: Processing of large-scale or custom design parts.

How 5-Axis Technology Works?

5-axis CNC milling machines are used for computer-aided mold manufacturing and are commonly found in advanced production facilities that frequently develop new products.

The cost of these systems can range from hundreds of thousands to several million dollars. Smaller-scale boat manufacturers often outsource new mold production to specialized companies that own these machines.

This technology accelerates the manufacturing of complex and large molds while improving accuracy — minimizing manual labor, time, and error risk.

Operation and Advantages:

- Speed and Continuity: 5-axis machines can operate 24/7, providing a major advantage in expanding product ranges and speeding up production.

- High Precision: Since every operation is fully computer-controlled, the resulting molds achieve exceptional accuracy.

- Production Process:

The project begins by cutting large foam blocks precisely to form an exact copy of the part to be produced.

Once shaped, the foam surface is coated with epoxy, polyester, or modeling paste.

The coating is then machined to the final dimensions of the actual mold.

The process is completed with sanding, mold release polishing, gelcoat, and fiberglass lamination.

- Time Savings:

For instance, producing the deck mold of a 45-meter yacht — a process that would take months by hand — can be completed in just a few weeks using a 5-axis CNC machine.