PROJECT MANUFACTURING & MACHINING PRODUCTION

High Precision, Reliable Production

At OYS Makina, we provide machining, semi-finished part processing, and steel construction body manufacturing services using our large-size Soraluce machining centers.

Our priorities are high precision, consistent quality, and on-time delivery in the machining of complex components.

Each project is evaluated according to the client’s technical drawings and quality expectations, and the most suitable production method, material, and surface treatment are selected and applied.

Why Choose Us

-

Soraluce CNC machine park suitable for machining large-scale components

-

Capabilities in drilling, milling, turning, and grinding operations

-

Experience in steel construction body manufacturing and assembly

-

Flexible production solutions through semi-finished product manufacturing

-

Careful monitoring of every process from technical drawing to delivery

-

Dimensional accuracy and quality assurance with control reports

-

Turnkey production with complementary processes such as heat treatment, surface grinding, and painting

Welded Construction Manufacturing

Welded Construction Manufacturing

Project Planning and Design

Project Planning and Design

Stress Relief and Sandblasting

Stress Relief and Sandblasting

Part Processing and Machining

Part Processing and Machining

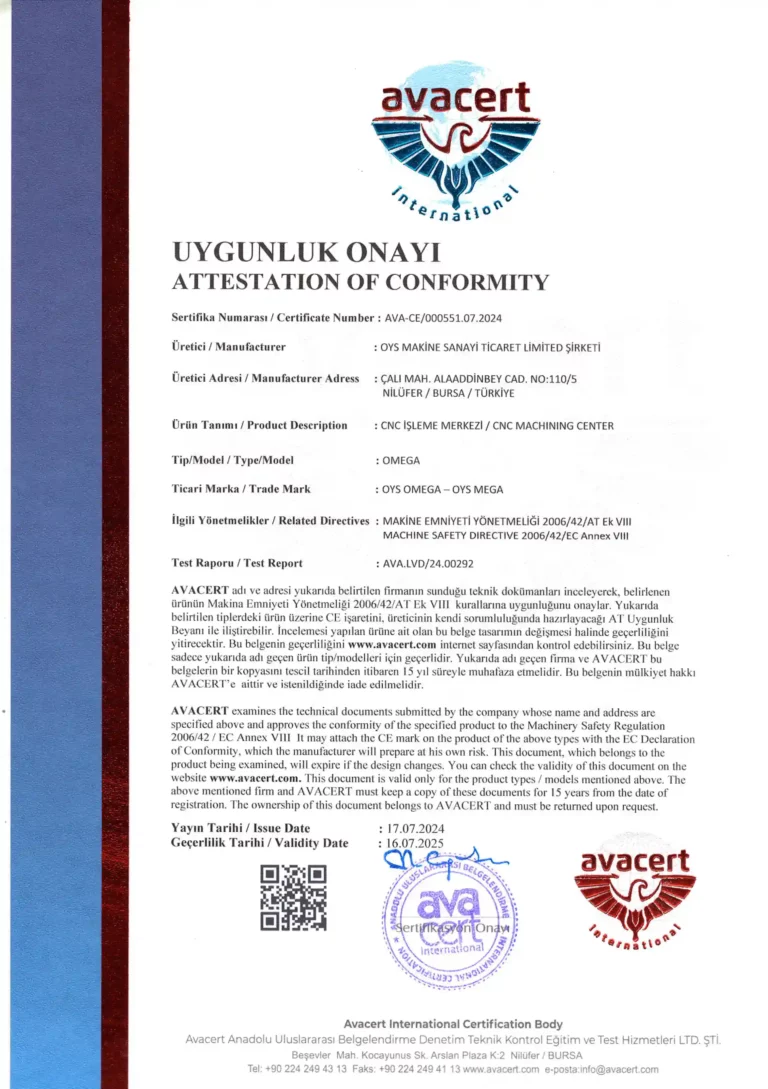

Certified Production Quality

Our company operates with the highest quality standards in both welded construction and machining.

With modern facilities, an experienced team, and a strong commitment to quality, we deliver reliable results in every project.

-

Production in compliance with quality standards for welded steel structures

-

Certified approach in precision machining, assembly, and inspection processes

-

High strength and accuracy in steel structures, machine bodies, and industrial equipment

Competent and Reliable Manufacturing Partner

We are a trusted partner in contract manufacturing and semi-finished production with certified quality assurance.

Our production processes fully comply with industry standards and environmental regulations.

-

Certified production capability in steel construction and machine components

-

Compliance with safety and environmental legislation

-

Transparent production processes open to inspection